- Home

- About us

- Products

- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

- Faqs

- News

- Certificate

- Contact us

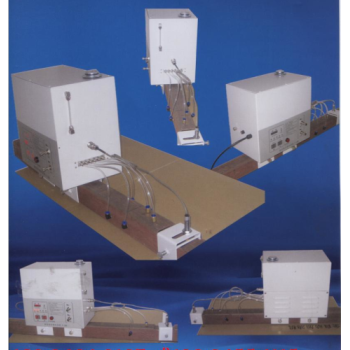

Conveyor Chain System full automatic lubricating machine

- FOB Price

US $100.01 - 100 piece

US $200.0101 - 200 piece

- group name

- Powder Coating Line Spare Part

- Min Order

- 1 piece

- brand name

- COLO powder coating equipment

- model

- Colo-ZQ-04

- Nearest port for product export

- SHANGHAI, NINGBO, QINGDAO, GUANGZHOU

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union

- Export mode

- Have the independent export and import right

- update time

- Wed, 18 Feb 2026 03:41:16 GMT

Paramtents

Brand name COLO

Model Colo-ZQ-04

Application Powder Coating Line

Packging & Delivery

-

Min Order1 piece

Briefing

Control unit+ lubricant injection

Detailed

Colo-ZQ-04 full automatic lubricating machine

This full automatic lubricating machine is designed for all kinds of automatic conveyor chain. The lubricating machine is divided into two parts, the control unit and the lubricant injection seat,which is connected with a transparent tube,this design in order to fit different types of chain,and use the transparent tube , it can easily check the lubricating situation.

This model is used for all various types of conveyor , Peilin chain lubrication and maintenance , protect the whole conveyor system from lack of lubrication, avoid causing failure, save maintenance cost.

Function

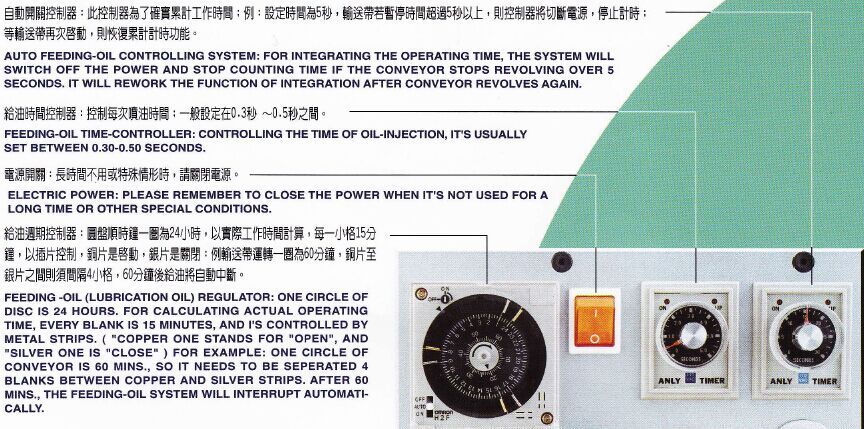

ZQ-04 microcomputer automatic lubricating machine, ZQ coating rail lubricating machine six point type, fixed time / ration / fixed point lubricating.

Function shows

Fixed time : the smooth operation of the machine, will affect the production costs of enterprises.

In order to reduce fault and pause, must do a good job of regular maintenance.This machine is equipped with "timing device", which is controlled by a touch switch of injection seat and can be started or stopped synchronously with the conveyor belt.According to the equipment working hours , set the lubricating cycle.

Ration: each of the mechanical equipment of the friction point or surface, required amount of lubricant is different.Less lubricant will cause Insufficient lubrication, more lubricant will waste, and even cause pollution.

The machine has six lubricant outlet, each one with the single output, and with an independent lubricant volume adjustment knob.

Fixed point lubricating: The lubrication point on the conveyor belt is ball, shoot nail and link point.For each point of the lubrication gap is very small.For giving lubricant to every point, the machine except the" touch switch ", also force to fixed point lubricating .If the lubricant outlet is not close to the lubrication point, the space is too small so need force to fixed point lubricating.Therefore, this machine is equipped with a wind speed adjustment knob to adjust the pressure, in order to achieve the absolute standard of "fixed point lubricating".

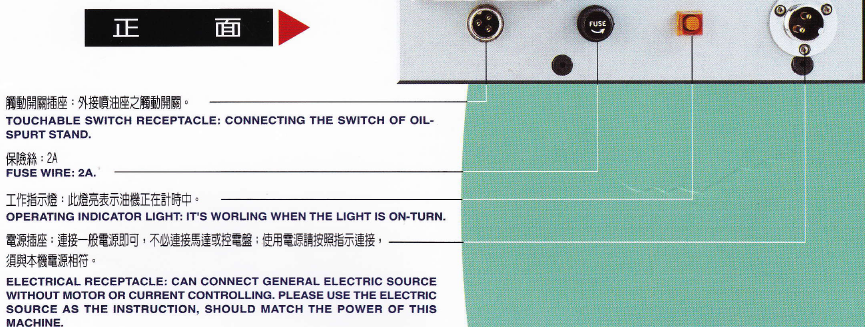

Basic installation method

1.Fix the machine on the chain track, each spray point should be installed on the track corresponding to the chain sprocket bearing, then, install the proximity switch on the track vertical wheel.

2.Power on (AC 220V)

3.Connect to the Air hose(8 mm)

Common troubles and troubleshooting

A.Power problem:

1.first check the power supply 220V is correct, then check the power switch, and then check whether the fuse is damaged,if all above checked is normal, then check if the control transformer in the control box can output 7V, 19V power , if no output, please replace the transformer.

B.Not only air refueling oil should be according to the methods of inspection

1 first check the lubricant supply system is normal (whether there is leakage around the lubricating pump)

2 to adjust the atomization adjustment knob with small pressure , to observe whether the lubricant will be ejected.

(If it is still no out of lubricant, please replace the lubricating pump)

C.When machine have the situation with no air and no lubricant

1.First check whether the operation of the intermittent indicator lights, if lights mean that the intermittent time is not working, this is normal.If want to work well, you can save the data in 15 seconds, which will be set to 2 seconds by manually forcing the operation or setting the time.

2 please check the proximity switch must be induced to the vertical wheel, when chain is running,proximity switch indicator light and no light ,when the panel indicator light and no light, so it works, otherwise should replace proximity switch.

3.check the solenoid valve working power supply is 24V, if there is no 24V please replace the solenoid valve can be.

D.An alarm sound or an alarm lights (which should add lubricant into the machine).

Colo is the leading powder coating equipment manufacturer in China, which provides high quality equipments

to more than 90 countries all oven the world with advanced manufacturing machines and professional

technicans. Colo offers a wide range of power coating equipments, namely powder coating machine, power

coating gun, spray booth, curing oven, automatic powder coating applicator, powder coating line and

replacement of spare parts for the famous brand in the world.