- Home

- About us

- Products

- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

- Faqs

- News

- Certificate

- Contact us

Hot sale model new compact design powder coating machine

- FOB Price

US $890.01 - 10 piece

- group name

- Powder Coating Gun

- Min Order

- 1 piece

- brand name

- COLO powder coating equipment

- model

- CL-668-L3

- Nearest port for product export

- SHANGHAI, NINGBO, QINGDAO, GUANGZHOU

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union

- Export mode

- Have the independent export and import right

- update time

- Mon, 23 Feb 2026 04:58:53 GMT

Paramtents

Condition New

Type Manual powder coating equipment

Substrate Steel

Application Powder Coating

Voltage 110/220V

Power(W) 50W

Weight 35KGS

Certification CE

Warranty 1 YEAR

Packging & Delivery

- 112cm x69cm x52cm

-

Min Order1 piece

Briefing

Intelligent and pulse with smart trolley

Detailed

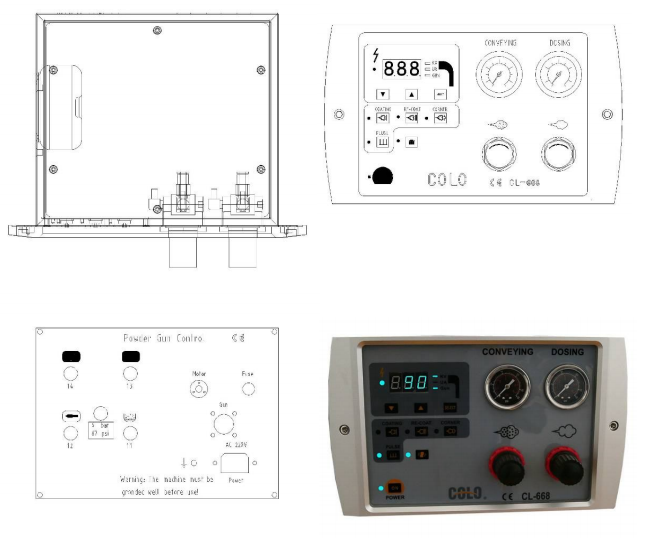

Hot sale model new compact design powder coating machine Control unit

It has pulse and one-touch intelligent function, and is good for flat parts, complex parts, recoat parts and conner.

Flat model: maximizes voltage for superior transfer efficiency with coating flats parts.

Complex model: adjust the voltage while holding current when coating complicated shapes and corners.

Recoat model: adjust the voltage and current automatically for recoating of parts.

Pulse model: rapidly recharges the powder to coat complex shapes.

y

y

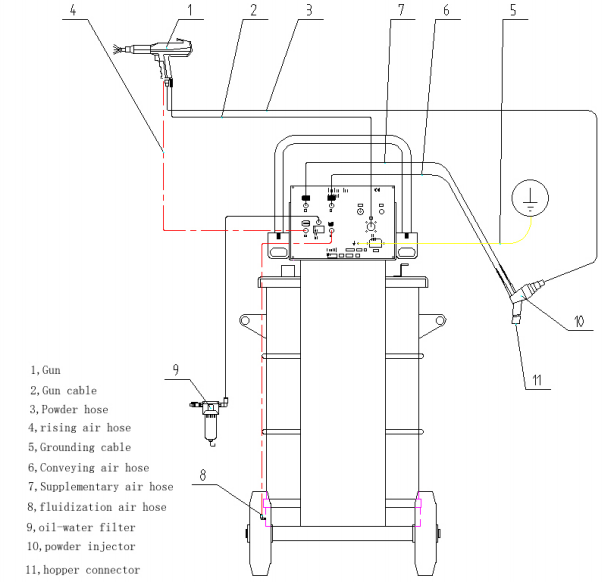

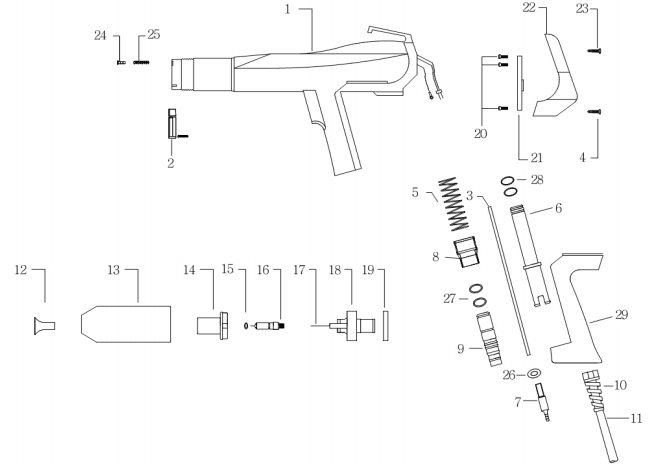

Spare parts of the powder coating application equipment

The powder coating equipment is built exclusively for electrostatic coating with organic powders.

The electrostatic powder manual coating equipment with the COLO-07 manual powder gun is ideally

suited for manual coating of objects in small series.

Power Source | AC220V/110V |

Frequency | 50~60Hz |

Power Consumption | 30W |

Voltage Output | 100kV |

Max. Current Output | 18uA |

Polarity | Negative |

Max. Injection Capacity | 650g(22.9oz.)/Min |

Air Consumption | MAX. 13Nm3/h |

Temperature Rage in use | -10~50℃(-14~22℉) |

Special features

1.Colo Newly integrated technology can lead to powder savings due to excellent transfer efficiency, easily penetrating corners

2.Colo Anti-static powder hose is developed with colo technology and it can prevent risk of fire by removing spark or electrical arc.

3.Prevents safety accidents caused by electrostatic shocks to the worker.

4.The new technology of one touch button installed in the gun enables you to clean inside of the gun and powder hose easily and quickly.

-INSTALLATION

→Propery ground all equipment in the spray area to an earth ground and maintain this ground

→Remove all containers of volatiles from the spray area

→Establish and maintain a grounded area for the spray operator

→The gun of xseries must be connect to xcontrol unit

→OPERATION

→The operator should hold the gun in his bare hand

→If gloves are worm ,the palm should be out to assure skin to metal contact

→The operator should wear shoes with conductive shoes e.g leather

Rubber shoes are not conductive .

→Ground the tip of the gun before cleaning or changing nozzles.

→When the gun is not in use , it should be hung so that the nozzle is within four inches of a grounded conductor

→The operator should wear a filter-type respiator anytime he is exposed to dusty conditions

→High pressure powder many cause injury ,Keep the rear switch “off” position in no –use condiction

MAINTENANCE

→Make a periodic confirmation of grounding to earh of all equipment in the spray area .

→Exercise good housekeeping practices , do not allow dirt or powder to accumulate on the feeder /powder unit , cable or gun.

→Keep the cabinet door

Colo has exported to more than 90 countries, such as Mexico, Colombia, Peru, Canada, the United States,

Brazil, Russia, Poland, France, Germany, Italy,Egypt, Vietnam, India, Saudi Arabia, South Africa and other countries.

We have built good long-term relationship with our customers. They come to visit our factory from time to time.

Colo is the leading powder coating equipment manufacturer in China, which provides high quality equipments

to more than 90 countries all oven the world with advanced manufacturing machines and professional

technicians. Colo offers a wide range of power coating equipments, namely powder coating machine, power

coating gun, spray booth, curing oven, automatic powder coating applicator, powder coating line and

replacement of spare parts for the famous brand in the world.

Welcome guests from all countries in the world to visit our factory.