- Home

- About us

- Products

- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

- Faqs

- News

- Certificate

- Contact us

Epoxy polyester powder coating non-toxic powder paint

- group name

- Powder Coatings

- Min Order

- 1 kilogram

- brand name

- COLO powder coating equipment

- model

- RAL,PANTONG

- Nearest port for product export

- SHANGHAI, NINGBO, QINGDAO, GUANGZHOU

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union

- Export mode

- Have the independent export and import right

- update time

- Wed, 28 Jan 2026 09:44:49 GMT

Paramtents

CAS No. no

Main Raw Material Epoxy

Usage Appliance Paint, Boat Paint, Building Coating, Car Paint, Electrical Insulating Varnish

Application Method Spray

State Powder Coating

powder coating powder paint

Packging & Delivery

-

Min Order1 kilogram

Briefing

Type: E/P/EP

Qulity: super

Detailed

Epoxy polyester powder coating non-toxic powder paint

We are a professional supplier of powder coating and we worked in this field for many years

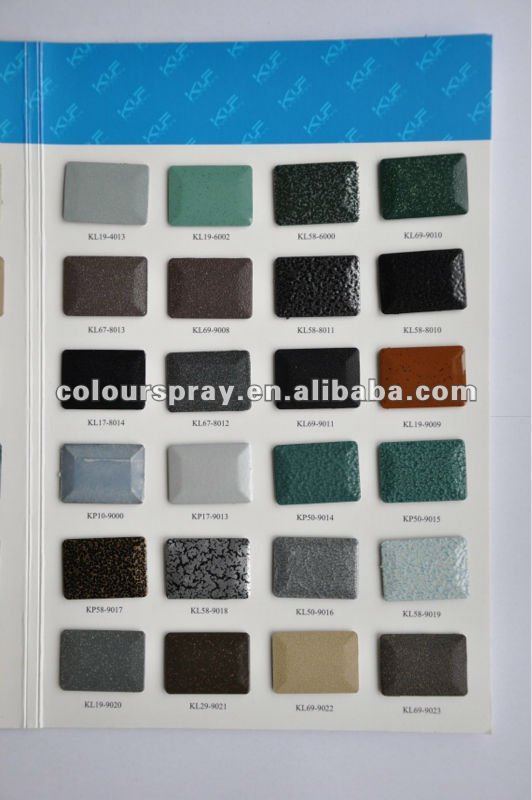

we provide many kind of powder paint, like a hammer, orange lines, grinding, highlights and inferior smooth, crack, flash of gold, silver and other effects, have appeared in recent years, high temperature resistant powder coating powder, powder painting at low temperature, high weather resistance, water resistance, acid powder powder powder, low temperature curing, UV curing powder powder and so on

Other name for this powder coating

Pure epoxy powder coating

Thermosetting powder coating

Electrostatic powder coating

Anti-environment powder coatintg

Non-toxic powder coating

Our powder coating is good quality we have UL,SGS ,ISO9001:2008

We supply powder coating to some big factory in China and other country.

Features

1.Good adhesive force and excellent flexibility and other each mechanical performance

2.Good chemicals resistance and corrosion prevention

3.Be more excellent than heat-resistance and light resistant stability of pure epoxy powder

4.Can be made into product with each brilliance and color; specific color and brilliance should be designated by users

5. Can be made into each kind of texture product such as ripple, hammer texture, metal effect, cotton like grain and crack etc.

COATING DISCRIPTION

Chemical type ; Epoxy/Polyester

Curing Condition ; 10-15 min/180oC-192oC

Adhesion ; 100%(ASTM D2794-93)

Hardness ; Minimum 1H-2H(ASTM D2134/93)

Erichsen Cupping ; Minimum 8 mm(DIN 53156)

Impact ; Direct ,minimum 50kg /cm2

; Reverse , minimum 40kg/ cm2

Flexibility ; Without Breaking

Salt Spray ; 500 hours (Zinc Phosfate),Pass no corrosion creep more than 2mm

fromscribe

New and recycled ; 75% new -25% recycled, without texture loss nor mechanical

coating mixture Properties

Chemical Resistance ; Good for most acids,alkalines,alcohols and oils at room

temperature

Use ; It is indicated for decorative and Protective end uses. It has excellent

appearance with improved heat stability and improved resistant

to Ultra violet light. these powder coatings are not recommended for

Long term exposure to ultra violet light nor aggressive environments.

All the Powders are Used for metal Furniture and This is a Raw Meteril.

Power manufacturing Process:

1. Mix raw material and auxiliary material for 3-4 min.

2. Melt extrusion in the machine at the temperature of 110-120 degrees centigrade.

3. Cooling to room temperature.

4. Grind the material to be particle.

5. Grind the particle to be powder.

6. Mix the powder with additives.(For special plastic powder)

7. Pack the powder to get the finished product.

Usage: Used us environmental coating instead of oil paint.

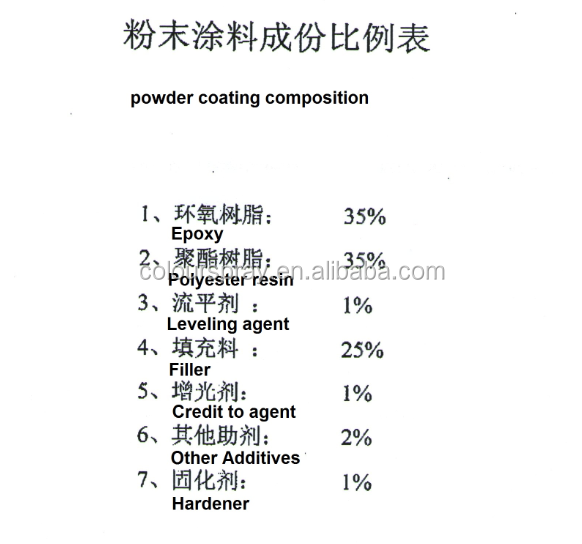

Other Quotation is what are the other Additives 2%: Additives includes increased electric agent, defoamer, micro powder wax additives.

Powder Constituent

Gloss level:

- High gloss (above 85%),

- Flat gloss (50%-85%),

- Semi gloss (10%-50%)

- Matt (below 10 %)

Package Specification

Health & Safety:

1.No hazardous ingredient.

2.No hazardous gas.

3.The inhalation of dusts should be avoided. An operator should wear an anti-dust mask and try best to avoid long time contact with the powder coatings.

4.The coatings stacked on the skin could be washed with soap.

5.Requirement of environment protection: the product doesn’t include arsenic, selenium, lead, hexavalent chromium, mercury,

stibium, cadmium and other heavy non-ferrous metals and is in fully conformity with requirement of RoHS environment protection.