- Home

- About us

- Products

- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

- Faqs

- News

- Certificate

- Contact us

automatic powder coating plant for aluminium profile

- group name

- powder coating line

- Min Order

- 1 set

- brand name

- COLO powder coating equipment

- model

- COLO-L

- Nearest port for product export

- SHANGHAI, NINGBO, QINGDAO, GUANGZHOU

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union

- Export mode

- Have the independent export and import right

- update time

- Sat, 21 Feb 2026 22:31:48 GMT

Paramtents

Condition New

Type aluminium profile Powder Coating Production Line

Substrate Iron

Coating Powder Coating

Voltage As required

Power(W) As required

Dimension(L*W*H) As required

Weight As required

Certification CE

Warranty 1 year

Packging & Delivery

-

Min Order1 set

Briefing

2,with conveyor automatic powder coating

3,With spray booth.

Detailed

automatic powder coating plant for aluminium profile

Specifications

1,aluminium profile electrostatic powder coating plant

2,with conveyor automatic powder coating

3,With spray booth,oven together

4,with CE

aluminium profile powder coating plant , this powder coating line is specially designed to provide quality powder coating aluminium profile

It consists of automatic powder coating booth with reciprocator and automatic powder coating gun,powder recycling unit,powder supplying hopper, electrical/diesel/LPG fired curing oven,conveyor unit and control panel.

Design for the workpiece with max size:(L)69000×(W)150×(H)1200mm

Max weight: 50kgs /pc

Voltage:380v 3 phases 50hz

Spray booth size: L6000mm×W1200mm×H2000mm

2 Pieces reciprocator, 8pieces automatic spray gun,2pieces manual powder spray gun

Curing oven size: (L)35000×(W)1000×(H)2500(mm)

Powder spray equipment:

COLO-500-PGC1

TECHNICAL DATA

Electrical data |

|

| |

Mains input voltage | 100-240 VAC |

| |

Operating frequency | 50-60 Hz |

| |

Input power | 50W |

| |

Nominal output voltage (to the gun) | max. 12 V |

| |

Nominal output current (to the gun) | max. 1 A |

| |

| IP54 |

| |

Ambient temperature range | 0°C - +40°C (+32°F - +104°F) |

| |

Max. operating temperature | 85°C (+185°F) |

| |

Approvals | CE |

| |

|

|

| |

Pneumatical data |

|

| |

Compressed air connection | 1/4" male quick release |

| |

Max. input pressure | 10 bar / 145 psi |

| |

Min. input pressure (while unit in operation) | 6 bar / 87 psi |

| |

Max. water vapor content of the compressed | air 1.3 g/m³ |

| |

Max. oil vapor content of the compressed air | 0.1 mg/m³ |

| |

|

|

| |

Connection Description |

|

| |

1.1 Air In | Compressed air connection (6-10 bar / 87-145 PSI) |

| |

2.1 Power | Mains cable connection (100-240 VAC) |

| |

2.2 Gun | Gun cable connection |

| |

1.4 |

|

| |

1.3 | Pict |

| |

1.2 |

|

|

COLO-2000D reciprocator

frequency-adjustable reciprocator is specially designed for high quality powder coating, it can carry up to 6pcs spray guns and optional for wet painting guns as well.

The benefits of colo-2000D: 80 storable programs frequency; Japanese Mitsubishi

Quick Details:

colo controllor cabinet

COLO- Sieving machine

We have specialized engineers to design and manufacture automatic plants with various processes as per customers requirement.This plant consists of several processes which are made into one by our specialized design.

Our services:

We deliver the goods to any ports in China,or deliver to the place as required

can ship within 30 days .

Packing: proper packing suitable for deliver

Services: we supply all equipments about the powder coating, such as booth, oven, reciprocator, gun, line, semi-line and plant and spare parts.

Why choose us:

design

drawing

illustration

commissioning

training

technical support

Quality Control:

testing in any step from material supplier to goods deliver.

Booths and oven size could Custom designed,Manual and automatic spray stations are also available.

Company Information:

1,products sample

2,machines

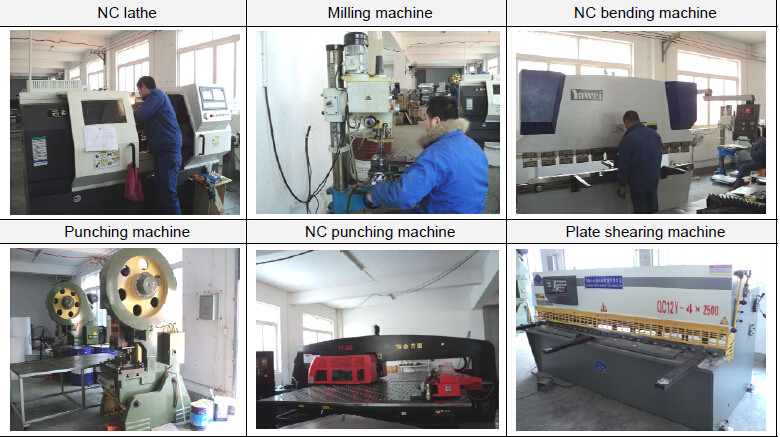

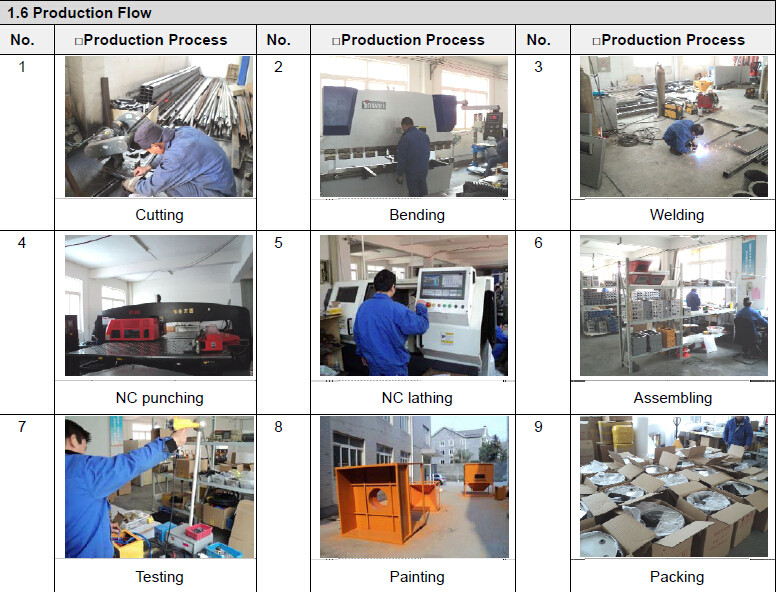

3,production flow:

Customer Visting:

powder coating gun, powder coating machine, powder coating system,powder coating equipment,powder coating control unit

COLO are specialized in complete electrostatic powder coating line, paint coating plants ,curing and drying ovens, cartridge type and cyclone recovery systems, spray booth, conveyor systems, Also we are supplier of powder coating, powder filters, powder coating machine,powder coating equipment,powder coatting gun,,Reciprocator, painting guns, pumps and their equipments.

More information,welcome to contact us as follow: