- Home

- About us

- Products

- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

- Faqs

- News

- Certificate

- Contact us

polypropylene Powder Coating Booths & Equipment

- group name

- Powder Coating Booth

- Min Order

- 1 set

- brand name

- COLO powder coating equipment

- model

- COLO-SC02

- Nearest port for product export

- SHANGHAI, NINGBO, QINGDAO, GUANGZHOU

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union

- Export mode

- Have the independent export and import right

- update time

- Tue, 03 Mar 2026 04:29:13 GMT

Paramtents

Condition New

Type Powder Coating Booths & Equipment

Substrate Iron

Coating Powder Coating

Voltage As required

Power(W) As required

Dimension(L*W*H) As required

Weight As required

Certification CE

Warranty 1 year

Packging & Delivery

-

Min Order1 set

Briefing

2,Full automatic control

3,Small area occupation

4,High productivity

Detailed

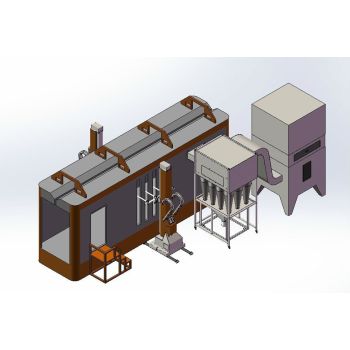

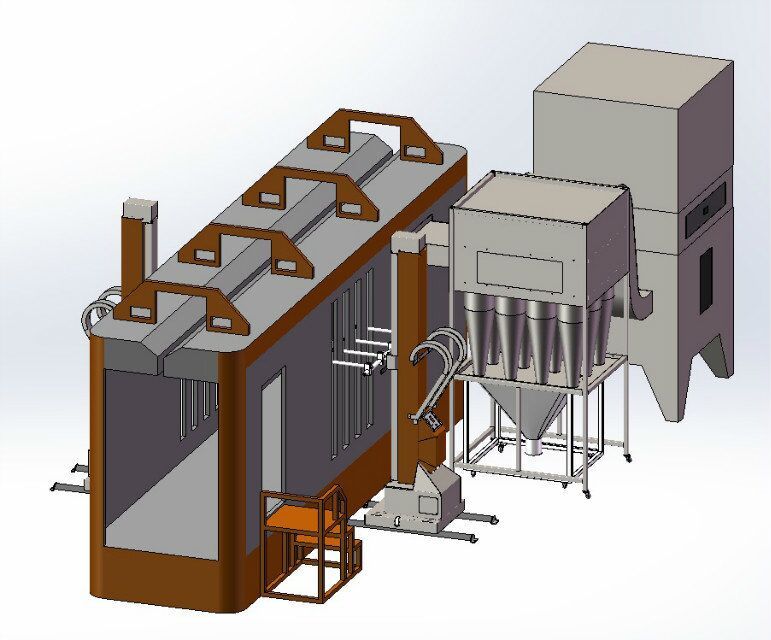

polypropylene Powder Coating Booths & Equipment

The polypropylene spray chamber with the multi-cyclonerecovery gives almost 100 % powder utilization. It is maintenance free and have very long life. The powder spray booth is easy to clean, resulting in a quick color change and is safe to operate. No powder spillage out of the booth and maximum recovery through the multi-cyclone results in pollution control.

why choose our polypropylene Multi-cyclone+ after filters recovery system powder spray booth?

The polypropylene canopy has a translucency that improves visibility inside

the booth and enhances gun transfer efficiency. It has a

long wearing, smooth, slick surface that is easy to clean

and does not attract powder or static buildup. This is the

most expensive booth material available.

the multi-cyclone is an improved technology based on mono-cyclone. The small height of clones allow for easymobility and faster cleaning operation

| Improved Transfer efficiency. |

| Pollution free operation. |

| safe to operate |

| Maximum recovery efficiency. |

| Durability. |

| Quick colour change. |

The polypropylene chamber with the multi-cyclone recovery consists coating chamber, multicyclone,filters with blower,motor & bin.

1,chamber:

It has a long wearing, smooth, slick surface that is easy to clean and does not attract powder or static build up.Chamber bottom is slopping in shape. So powder collection is easy. To suck the powder, at the bottom there is a loose 'C' channel which sticks to the side wall when blower is on.

2,Multicyclone:

This consists of the cluster of very small cyclones which are less in diameters& height. The Powder sucked from the chamber gets distributed in to eachsmall cyclone. Due to small diameter & very high air velocity, maximumpowder moves along the periphery of cyclone. As each small cyclone handlessmall amount of powder, the efficiency of complete multicyclone is as high as98.5%. Due to such high efficiency maximum powder is saved & so cost of thebooth is recovered within very less time.

2,filters with blower,motor

For Powder recovery aconical bin is designed to be attached below multicyclone. To remove the binwith powder, a separate trolley is given below the bin.

DuctlessConstruction:

In between multicyclone& chamber there is no separate duct piece with bends. There is no nutbolting construction which is very very tedious for colour change & takeslot of time. As a duct there is just a loose 'C' channel. So this booth is veryeasy for cleaning. Saving time and labor.

technical data of spray booth

| Outside size | 4000 x W 1200 x H 3000mm |

| Workpiece opening | W700x H1800mm |

| Touch up opening | W700 X H1500mm |

| Auto gun opening | W 100 x H 1750 mm |

| Exhaust | 8,000 M3/Hr(150mm/Aq) |

| Fan type | Anti-explode Fan |

| Booth Carbin material | SUS304 |

| Fluorescent lamp | 40W |

| Cartridges filter | 10pcs |

| Booth the average wind speed | 0.5M/Sec.(150mm/Aq) |

| Voltage | 380V |

For different models:

Different Models:

Depending upon size of the article, coating requirements, material handlingrequirements we have designed some standard models. As a special requirementdifferent customized models are also developed.

Velocity of booth should be:

| Appropriate enough so that maximum powder should be attracted on the article. |

| If suction velocity is more, more amount of powder will be sucked towards cyclone & less on article. |

| If suction velocity is less, then powder will come out from cutout & surroundings will be polluted. |

Spray booth Selection Criteria:

| Easiness in colour change , No. of colour change ,Frequency of colour change. |

| Selection of Booth design. |

| Size of Article ,Weight of Article. |

| Selection & type of Track / Trolleys from 1 side or 2 sides. |

| System of track / trolleys. |

| Any other type of material handling. |

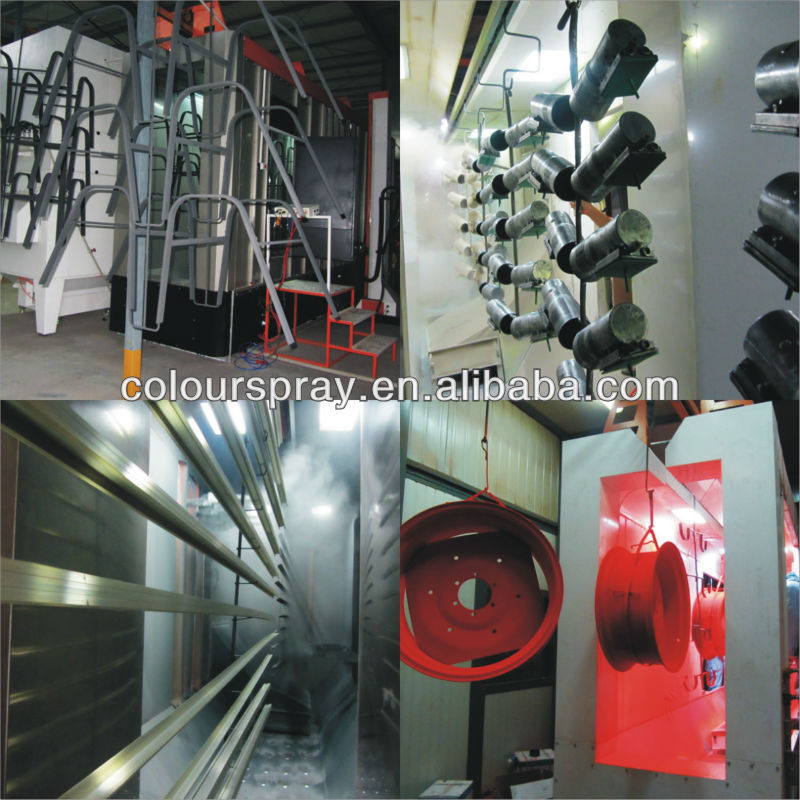

application

factory

packing and deliver

packing and deliver

Show

Show

welcome to contact for talking about the details by the way as follow:

COLO Powder Coating Systems is a top supplier of powder coating systems and powder coating equipment including manual powder coating equipment, automatic equipment, spray booths,ovens and spare parts for itw gema, wagner, nodrson, kci famous brand in China.

China Powder coating gun, China powder coating machine, China powder coating system, China powder coating equipment, powder coating control unit,manual powder coating machine,manual powder coating equipment, manual powder coating gun, electrostatic powder coating equipment