- Home

- About us

- Products

- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

- Faqs

- News

- Certificate

- Contact us

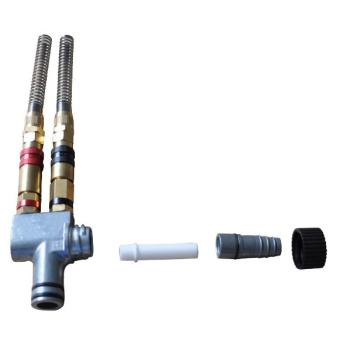

Plug-in powder injector for organic powders 391 530

- group name

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- Min Order

- 1 piece

- brand name

- COLO powder coating equipment

- model

- 391 530

- Nearest port for product export

- SHANGHAI, NINGBO, QINGDAO, GUANGZHOU

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union

- Export mode

- Have the independent export and import right

- update time

- Tue, 16 Dec 2025 17:55:34 GMT

Paramtents

Used for electrostatic powder coating

how long deliver 1-2 days after payment

MOQ 1 piece

lifetime depend on different type powder

Packging & Delivery

-

Min Order1 piece

Briefing

Used to convey normal organic powders between

the powder hopper and the powder gun.

Detailed

Plug-in powder injector for organic powders 391 530 with coded quick-release connections

The injector is used to convey normal organic powders between the powder hopper and the powder gun. The injector is

supplied with a PTFE insert sleeve as standard. The plug-in injector allows fast cleaning and easy handling because it can be

detached from the powder hopper without using any tools. All connections are plug-in and not interchangeable (when using in

manual equipment).

Structure of the powder injector

Principle of the injector

If air flows through the nozzle into the cavity, a vacuum is created in the cavity (see figure below). This vacuum causes powder to

be drawn up the suction tube and into the cavity. A powder/air mixture is created. The forward air velocity at the nozzle conveys

the powder/air mixture through to the powder hose to the gun.

Available spare parts for powder injector

powder injector (complete, pos. 1-9) 391 530

1 Injector body (without pos. 2) 1000 132

2 O-ring - Ø 16x2 mm 231 517#

3 Insert sleeve - PTFE 377 724#

4 Hose connection (complete, incl. pos. 4.1) 387 827

4.1 O-ring - Ø 15x1 mm 266 930#

5 Threaded sleeve 387 819

6 Check valve conveying air (red marking) - complete (incl. pos. 8 and 9) 261 211

7 Check valve supplementary air (black marking) - complete (incl. pos. 8 and 9) 261 203

8 Ball 240 168

9 Spring 240 176

10 Quick release coupling red for conveying air hose - Ø 8/6 mm 261 645

11 Quick release coupling for supplementary air hose - Ø 8/6 mm 261 637

12 Conveying air hose - Ø 8/6 mm (red) 103 500*

13 Supplementary air hose - Ø 8/6 mm (black) 103 756*

14 Quick release coupling for hose - Ø 8/6 mm 203 181

Powder hose - type 1001, PUR, Ø 16/11 mm (standard for automatic guns) 103 012*#

Powder hose - type 1004, PVC, Ø 16/11 mm (standard for manual equipment) 103 128*#

Powder hose - type 1005, PVC, Ø 20/12 mm (for manual equipment) 100 080*#

Powder hose - type 66, POE, Ø 16/11 mm, with conductive strip (for automatic

guns) 105 139*#

Powder hose - type 74, POE, Ø 15/10 mm, with conductive strip (for automatic

guns) 1001 673*#

Powder hose - type 75, POE, Ø 18/12 mm, with conductive strip (for automatic

guns) 1001 674*#

Colo is the leading powder coating equipment manufacturer in China, which provides high quality equipments

to more than 90 countries all oven the world with advanced manufacturing machines and professional

technicans. Colo offers a wide range of power coating equipments, namely powder coating machine, power

coating gun, spray booth, curing oven, automatic powder coating applicator, powder coating line and

replacement of spare parts for the famous brand in the world.