- Home

- About us

- Products

- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

- Faqs

- News

- Certificate

- Contact us

powder injector 391 530#

- group name

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- Min Order

- 1 piece

- brand name

- COLO powder coating equipment

- model

- 391 530

- Nearest port for product export

- SHANGHAI, NINGBO, QINGDAO, GUANGZHOU

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union

- Export mode

- Have the independent export and import right

- update time

- Thu, 05 Feb 2026 00:23:21 GMT

Paramtents

Used for electrostatic powder coating

how long deliver 1-2 days after payment

MOQ 1 piece

lifetime depend on different type powder

Packging & Delivery

-

Min Order1 piece

Briefing

The injector is used to convey normal organic powders between

the powder hopper and the powder gun.

Detailed

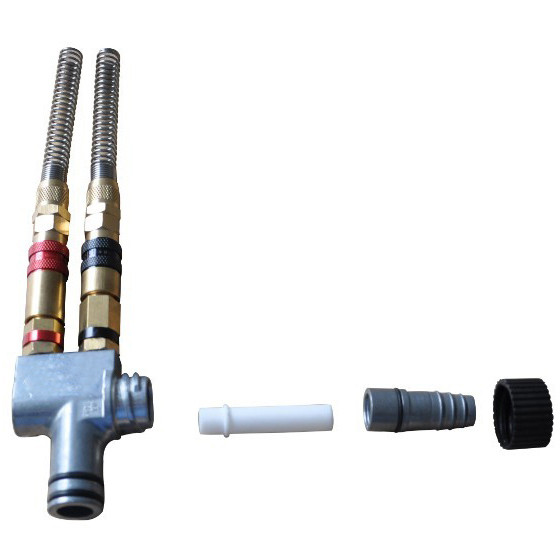

powder injector 391 530#

The injector is used to convey normal organic powders betweenthe powder hopper and the powder gun.

The OptiFlow plug-in injector allows fast cleaning and easy handling becauseit can be detached from the powder hopper without using anytools. All connections are plug-in and not interchangeable (when using inmanual equipment).

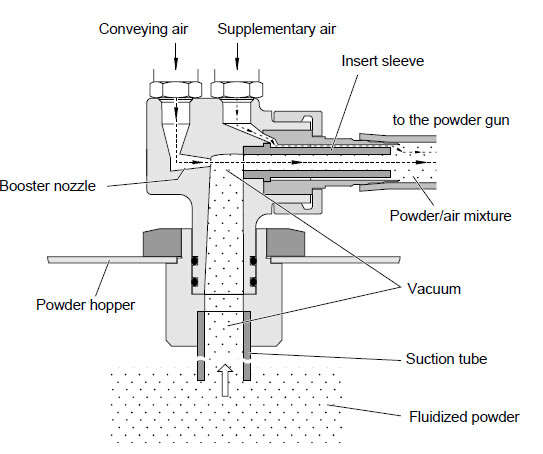

Principle of the injector and influence of supplementaryair

If air flows through the nozzle into the cavity, a vacuum is created in thecavity (see figure below).

This vacuum causes powder to be drawn upthe suction tube and into the cavity. A powder/air mixture is created. Theforward air velocity at the nozzle conveys the powder/air mixture throughto the powder hose to the gun.

The concentration of the powder/air mixture, and with it, the powder outputdepends on the conveying air pressure and supplementary air pressure,the quality of the powder, the length of the powder hose, the diameterof the powder hose, the number of coils in the hose, the difference inthe height between the gun and injector, and the type of nozzle. Thecondition of the insert sleeve is of great importance, because wearcauses the powder output to sink drastically.