- Home

- About us

- Products

- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

- Faqs

- News

- Certificate

- Contact us

Vibration manual spray system

- group name

- Powder Coating Gun

- Min Order

- 1 piece

- brand name

- COLO powder coating equipment

- model

- COLO-800D-2L-B

- Nearest port for product export

- SHANGHAI, NINGBO, QINGDAO, GUANGZHOU

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union

- Export mode

- Have the independent export and import right

- update time

- Sat, 31 Jan 2026 17:10:40 GMT

Paramtents

Condition New

Type Coating Spray Gun

Substrate Aluminum

Coating Powder Coating

Voltage 100-240V

Power(W) 50W

Dimension(L*W*H) 123*80*49CM

Weight 55KGS

Certification CE

Warranty 1 YEAR

After-sales Service Provided Engineers available to service machinery overseas

powder gun electrostatic

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Vibration manual spray system for ast colour changes, Box powder coating equipment ,New intelligent powder coating equipment, Digital display

This intelligent Digital powder coating machine COLO-800D-2L-B This model use the

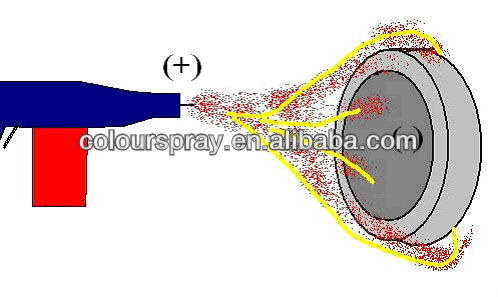

The process of the coating is like this: The powder is fluidized in the powder box. The injectors transport the powder through the hoses to the guns. The guns spray a powder/air mixture onto the workpieces. Character: Controller has one-touch intelligent operation button good for flat parts, complicated parts and recoat parts This machine is suitable for the coating of simple, flat workpieces This machine is suitable for the coating workpieces with complicated shapes

Brief Introduction

The process of the powder coating is like this: The powder is fluidized in the powder hopper. The injectors transport the powder through the hoses to the guns. The guns spray a powder/air mixture onto the workpieces

Specification

0-100 Digital Adjustable KV Fully Adjustable Amperage With three setting program,for flat shape workpiece,complicated shape workpiece,recoating,easy for operation. Fully Adjustable Air for Pump on Pressure, Dosage and Nozzle Rinsing Air. Comes with Full Array of Nozzle Assortment. Field Tested and Proven to operate in the toughest environments. Comes with different array of delivery systems: Because this system is specially balanced for the maximum spray capability with the Smoothest Finish Possible.

Techincal data:

| Electrical data | |

| Mains input voltage | 100-240 VAC |

| Operating frequency | 50-60 Hz |

| Input power | 50W |

| Nominal output voltage (to the gun) | max. 12 V |

| Nominal output current (to the gun) | max. 1 A |

| IP54 | |

| Ambient temperature range | 0°C - +40°C (+32°F - +104°F) |

| Max. operating temperature | 85°C (+185°F) |

| Approvals | CE |

| Pneumatical data | |

| Compressed air connection | 1/4" male quick release |

| Max. input pressure | 10 bar / 145 psi |

| Min. input pressure (while unit in operation) | 6 bar / 87 psi |

| Max. water vapor content of the compressed | air 1.3 g/m³ |

| Max. oil vapor content of the compressed air | 0.1 mg/m³ |

| Packing Dimensions | |

| Length | 123CM |

| Width | 80CM |

| Height | 49CM |

| Weight | approx. 55kgs |

at same time with hopper feed model

COLO-800D-2L Applicable to a large number of coating job with powder keg 50L

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. The coating is typically applied electrostatically and is then cured under heat to allow it to flow and form a "skin". The powder may be a thermoplastic or a thermosetpolymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as "whiteware," aluminium extrusions, and automobile and bicycle parts. Newer technologies allow other materials, such as MDF (medium-density fibreboard), to be powder coated using different methods.

The powder coating process involves three basic steps:

- Part preparation or the pre-treatment

- The powder application

- Curing

COLO Powder Coating Systems is a top supplier of powder coating systems and powder coating equipment including automated equipment, spray booths and spare parts famous brand in china.

FACTORY

Any questions,please contact us

powder coating gun, powder coating machine, powder coating system,powder coating equipment,powder coating control unit