- Home

- About us

- Products

- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

- Faqs

- News

- Certificate

- Contact us

electrostatic powder coating machine

- group name

- Powder Coating Gun

- Min Order

- 1 piece

- brand name

- COLO powder coating equipment

- model

- CL-131S

- Nearest port for product export

- SHANGHAI, NINGBO, QINGDAO, GUANGZHOU

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union

- Export mode

- Have the independent export and import right

- update time

- Wed, 28 Jan 2026 05:39:51 GMT

Paramtents

Condition New

Type Coating Spray Gun

Substrate Copper

Coating Powder Coating

Voltage 100-240 VAC

Power(W) 50W

Dimension(L*W*H) 56*52*69CM

Weight 35KGS

Certification CE

Warranty 1 YEAR

After-sales Service Provided Engineers available to service machinery overseas

powder coating machine manual

function surface treatment

technical date pulse

powder hopper 45L stainless steel

type intelligent model

Packging & Delivery

-

Min Order1 piece

Briefing

1.intelligent powder coating machine

2.quick color changes

3.intelligent

4,CE

Detailed

Electrostatic powder coating machine ,The CL-131S electrostatic powder manual coating equipment with the

COLO-06 manual powder gun is ideally suited for manual coating of objects in larger series.

The process of the coating is like this :the powder is fluidized in the powder hopper. The injectors transport the powder through the hoses to the guns . The guns spray a powder/air mixture onto the workpieces.

Typical characteristics

- Processing the powder from the fluidized powder hopper

- Quick and simple color change

- Supplied ready for use

- Available with one or two guns (extensible)

CL-131S Electrostatic Powder Manual Coating Equipment,is designed exclusively for electrostatic coating with powder.

0-100 Digital Adjustable KV

Fully Adjustable Amperage

Interchangeable with the Gema original equipment OPTIFLEX

Fully Adjustable Air for Pump on Pressure, Dosage and Nozzle Rinsing Air.

Comes with Full Array of Nozzle Assortment.

Field Tested and Proven to operate in the toughest environments.

Comes with different array of delivery systems:

Because this system is specially balanced for the maximum spray capability with

the Smoothest Finish Possible.

Configuration:

A control unit power supply cable

- A air filter

- A air pressure regulator

- A fluidized powder hopper

- A plug-in injector

- An manual powder gun with gun cable, powder

hose, rinsing air hose and standard nozzle set.

- Pneumatic hoses for conveying air (red), supplementary

air (black) and fluidizing air (black)

powder hose

Ground wire

TECHNICAL DATA

| Electrical data | |||

| Mains input voltage | 100-240 VAC | ||

| Operating frequency | 50-60 Hz | ||

| Input power | 50W | ||

| Nominal output voltage (to the gun) | max. 12 V | ||

| Nominal output current (to the gun) | max. 1 A | ||

| IP54 | |||

| Ambient temperature range | 0°C - +40°C (+32°F - +104°F) | ||

| Max. operating temperature | 85°C (+185°F) | ||

| Approvals | CE | ||

| Pneumatical data | |||

| Compressed air connection | 1/4" male quick release | ||

| Max. input pressure | 10 bar / 145 psi | ||

| Min. input pressure (while unit in operation) | 6 bar / 87 psi | ||

| Max. water vapor content of the compressed | air 1.3 g/m³ | ||

| Max. oil vapor content of the compressed air | 0.1 mg/m³ | ||

| Packing Dimensions | |||

| Length | 120CM | ||

| Width | 79CM | ||

| Height | 73CM | ||

| Weight | approx. 55kgs | ||

| Connection Description | |||

| 1.1 Air In | Compressed air connection (6-10 bar / 87-145 PSI) | ||

| 2.1 Power | Mains cable connection (100-240 VAC) | ||

| 2.2 Gun | Gun cable connection | ||

| 1.4 |

| ||

| 1.3 | Pict | ||

| 1.2 |

| ||

| Grounding connection | Pict |

Packing Dimensions

Length: 69cm

Width: 52cm

Height: 56cm

Weight: 37 kgs.

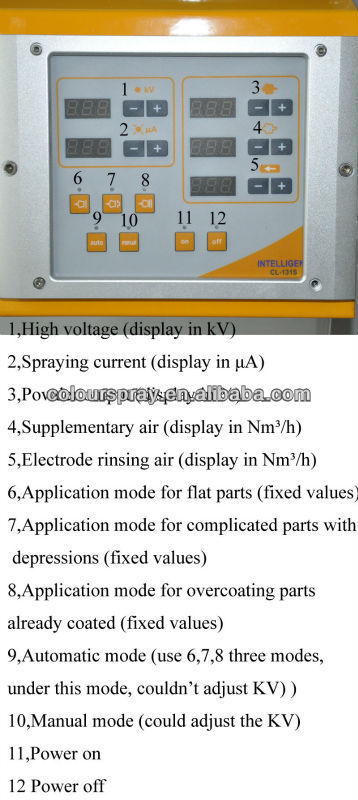

Manual coating equipment Function description

the powder gun through the powder hose . The powder is electrostatically

charged at the nozzle of the gun. In addition, an electrostatic field is

created between the gun nozzle and the grounded object. The charged

powder spray remains adhered to the surface of the object.

The powder is fluidized by air forced through a porous plastic plate from

below. The powder acquires, thereby, fluid-like characteristics.

The conveying air, supplementary air, and rinsing air are set on the control

Unit

The process of the coating is like this: The powder is fluidized in the powder hopper. The injectors transport the powder through the hoses to the guns. The guns spray a powder/air mixture onto the workpieces

related equipments

spray booth

For more details for this spray booth ,pls visit http://www.........../product-gs/491056417/Electrostatic_Powder_Coating_booth.html

Curing oven

for more details of this curing oven,pls visit

http://www.........../product-gs/590452605/Electrostatic_powder_coating_oven.html

COLO Powder Coating Systems is a top supplier of powder coating systems and powder coating equipment including manual powder coating equipment, automatic equipment, spray booths,ovens and spare parts for itw gema, wagner, nodrson, kci famous brand in China.

China Powder coating gun, China powder coating machine, China powder coating system, China powder coating equipment, powder coating control unit

We also can supply powder parts replacement of famous powder coating machine , same function,but times lower price!!!