- Home

- About us

- Products

- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

- Faqs

- News

- Certificate

- Contact us

Frame Powder Coating Gun

- group name

- Powder Coating Gun

- Min Order

- 1 set

- brand name

- COLO powder coating equipment

- model

- COLO-800D-2, 800

- Nearest port for product export

- SHANGHAI, NINGBO, QINGDAO, GUANGZHOU

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union

- Export mode

- Have the independent export and import right

- update time

- Fri, 30 Jan 2026 21:45:31 GMT

Paramtents

Condition New

Type electrostatic powder spray gun

Substrate Steel

Coating Powder Coating

Voltage 100-240V

Power(W) 50W

Dimension(L*W*H) 120*80*80CM

Weight 50KGS

Certification CE

Warranty 1 year

After-sales Service Provided Overseas third-party support available

electrostatic painting equipment powder coating equipment

type electrostatic powder spray gun

Packging & Delivery

-

Min Order1 set

Briefing

2. Both operators each have a powder coating gun, control unit and powder injector

Detailed

Frame Powder Coating Gun Powder coating equipment , manual electrostatic spray guns

Electrostatic powder coating manufacture in China,Electrostatic Powder Coating Machine,Powder spraying gun, powder spray gun, metallic powder coating system, electrostatic powder spraying unit, electrostatic powder spraying.electrostatic spray application system,Surface Finishing Equipment.

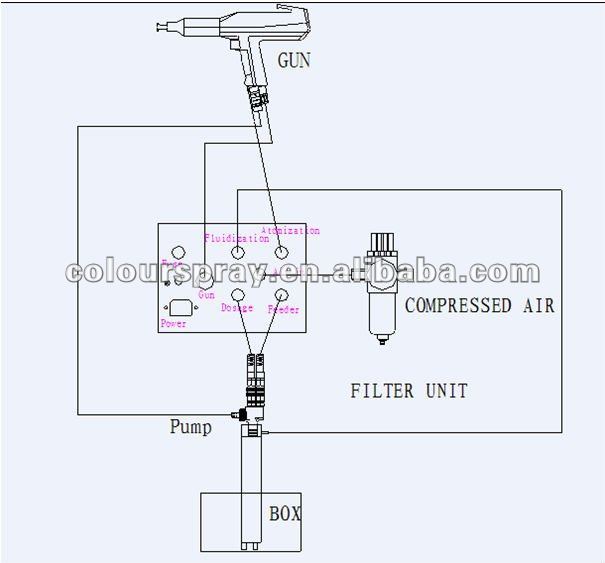

Both operators each have a powder coating gun, control unit and powder injector that use powder from the same powder hopper.

1,Dual Unit powder application systems 2,Gema Optiflex model 4, Both operators each have a powder coating gun, control unit and powder injector that use powder from the same powder hopper. Technical Data: this machine is good for powder coating rims or powder coating wheels, and easy to chnge color Manual Powder Coating System largest electrostatic voltage: 90-100kv Min. Compressor 87 PSI, Hose Length 17 Ft, For Use With All Powder Paints Include powder spray gun, Control Unit, powder hopper, Powder Injector, Trolley and Vibration System, Cables and Hoses →Technical Data Electrical data Power range 110v/220V Frequency 50HZ /60hz Temperature range in use -10 °C+50 °C

Powder Gun Gun weight: ……………… 500G Rated output voltage ……… 24VDC Input voltage …………… - 200kv Maximum output current ……… 180Ua(max) Maximum output voltage………… 0-100KV ( adjustable) Maximum powder injection :……… 600g/min Polarity ……………… negative (-) Pneumatic data Maximum input-air pressure ………….. 10kg/cm Optimum input-air pressure…….. 6kg/cm Minimum input-air pressure …… 4kg/cm Maximum water vapor content or compressed air ….. 1.4g/N m3 Maximum oil vapor content of compressed air …….. 0.1ppm Maximum compressed-air consumption……… 13.2 m3/h

Dimensions

Connecting guide Manual Gun

|

El polvo fluidizado se aspira de la tolva hacia el inyector mediante el aire

de transporte (1 – manguera de color rojo), y la mezcla aire/polvo pasa a

través de la manguera para polvo, hasta llegar a la pistola (2) donde recibe

una carga electrostática en la boquilla de la misma. Además, se

crea un campo electrostático entre la boquilla de la pistola y el objeto conectado

a tierra. El polvo aplicado, con su carga electrostática, se adhiere

a la superficie del objeto.

El polvo se fluidiza gracias al aire a presión que pasa a través de una

placa de plástico porosa, desde abajo. Mediante este proceso, el polvo

adquiere un aspecto líquido.

El aire de transporte, de suplementario, de fluidización y el de limpieza

se establecen en el módulo de control.