- Home

- About us

- Products

- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

- Faqs

- News

- Certificate

- Contact us

manual powder painting system

- group name

- Powder Coating Gun

- Min Order

- 1 set

- brand name

- COLO powder coating equipment

- model

- COLO-S-04

- Nearest port for product export

- SHANGHAI, NINGBO, QINGDAO, GUANGZHOU

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union

- Export mode

- Have the independent export and import right

- update time

- Fri, 06 Feb 2026 13:56:41 GMT

Paramtents

Condition New

Type Coating Production Line

Substrate Iron

Coating Powder Coating

Voltage 380V

Power(W) 2.24KW

Dimension(L*W*H) L8000 x W 1700 x H 3000mm

Weight 2000KGS

Certification CE

Warranty 1 year

After-sales Service Provided Engineers available to service machinery overseas

MOQ 1 piece

Guarantee 1 year

Exhaust: 8,000 M3/Hr(150mm/Aq)

fan type Anti-explode Fan

Booth Carbin material SUS304

Fluorescent lamp 40W

Booth the average wind speed: 0.5M/Sec.(150mm/Aq)

Packging & Delivery

-

Min Order1 set

Briefing

2,Full automatic control

3,Small area occupation

4,High productivity

5,CE

Detailed

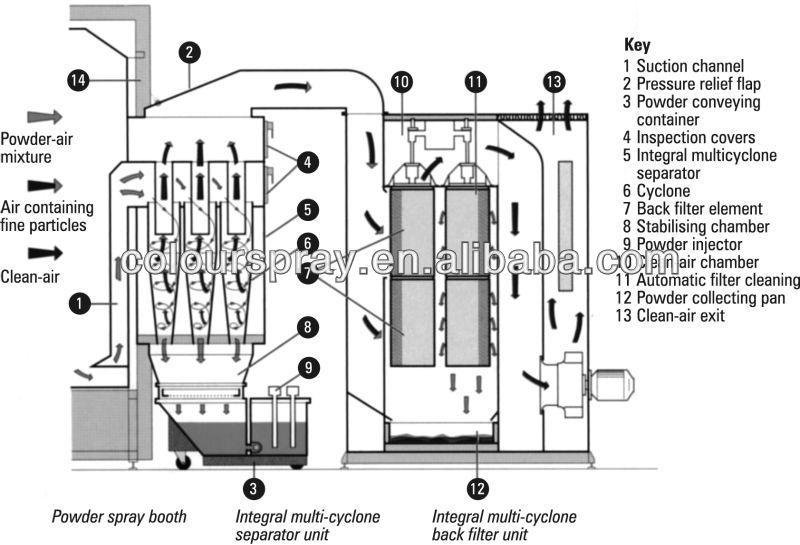

multi cyclone after filter powder recovery system of automatic furniture furniture paint spray machine .

highest power recovery and fast colour change

The powder booth is one of the most critical components of the product finishing process,this Multi-level cyclone separator plus double grades recycling, to recycle more powder and eliminate powder leakage.

Benefits of our Powder Booths

1,Multi-Cyclone recovery system ensures extremely high levels of powder recovery 98% .

2,Faster Color Change:The Bottom of the Booth prevents accumulation of the powder and makes it very easy for cleaning and quick Color change.

3,Higher life of cartridge filter with unique Rotary wing cleaning mechanism

Technical Date:

| Outside size |

|

| Workpiece opening | W700x H1800mm |

| Touch up opening | W700 X H1500mm |

| Auto gun opening | W 100 x H 1750 mm |

| Exhaust | 8,000 M3/Hr(150mm/Aq) |

| Fan type | Anti-explode Fan |

| Booth Carbin material | SUS304 |

| Fluorescent lamp | 40W |

| Cartridges filter | 10pcs |

| Booth the average wind speed | 0.5M/Sec.(150mm/Aq) |

| Voltage | 380V |

The instruction of the spray booth

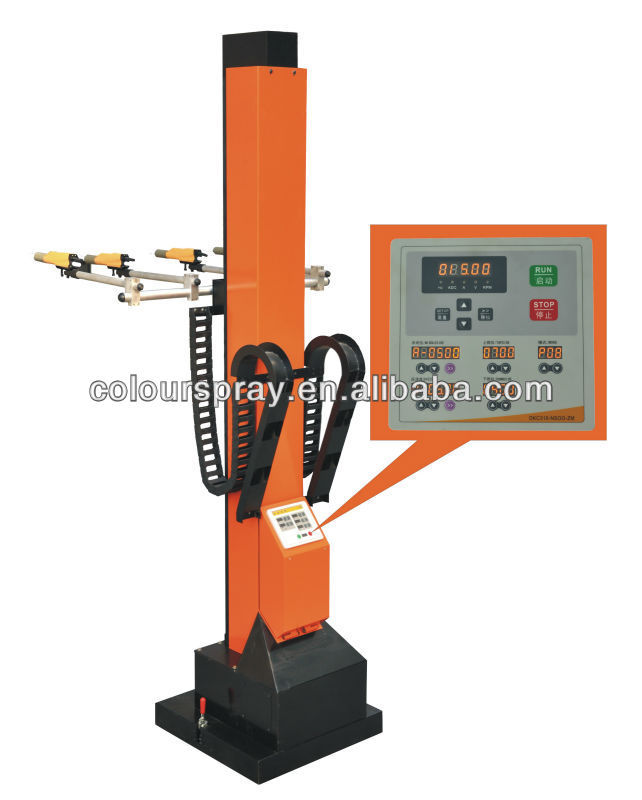

Gun Movers

Automatic Reciprocator (reciprocating machine) (Work with Electrostatic Powder Coating Gun) With several electrostatic powder coating gun on the reciprocator Japan Mitsubishi Transducer & PLC controlled

Four automatic spray gun rods(qty of the rods can be ordered)

The COLO-5000-800D Control system with the 800D automatic powder spray

guns especially designed to meet the requirements of serial production

in powder coating, where reliability in automated operation, easy to

handle operation and security are the most projecting advantages for the user.

The type and the number of installed control units could make as your

requirements.

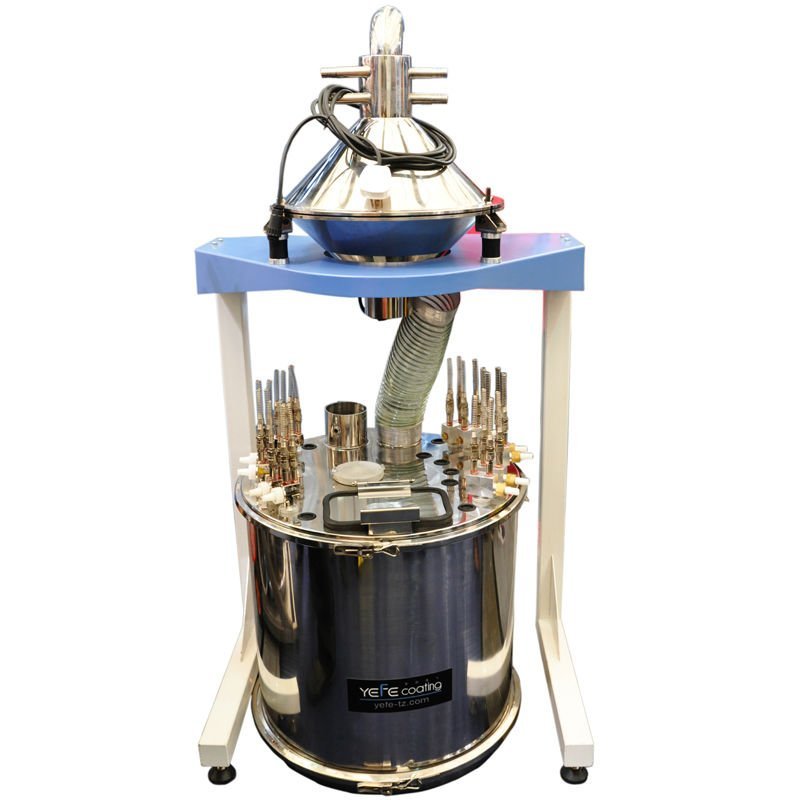

Powder sieving machine

The system is able to continuously sent the powder being dropped during the

process of spraying to the upper part of the butterfly powder screen and then

the selected powder is sent to the centralized powder supply barrel which is in

charge of continuously supplying powder to automatic guns or manual guns

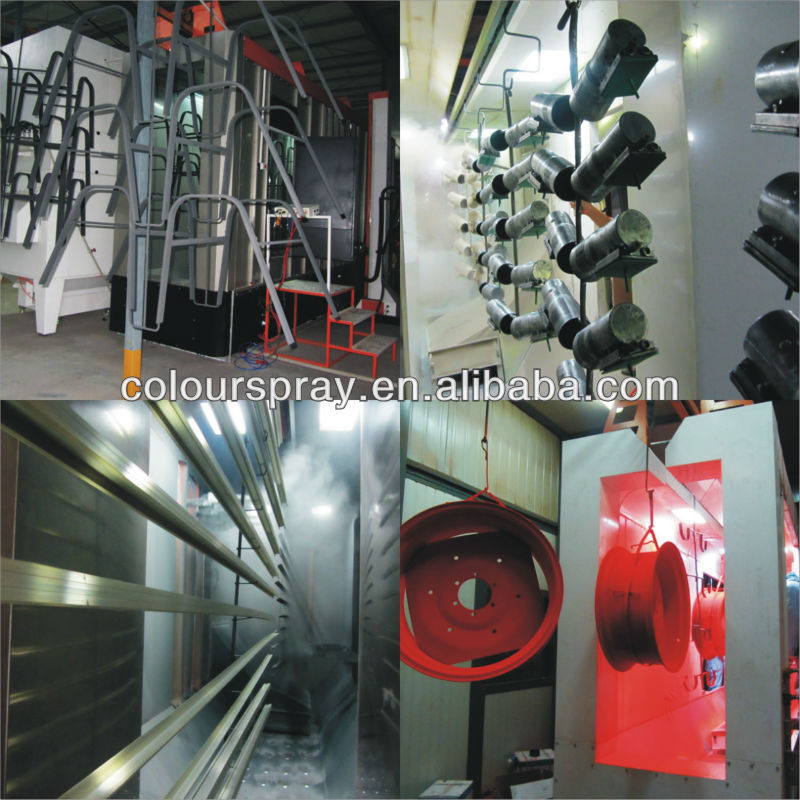

The spray booth is manufacture according to your requirements.

All powder coating booths are formed on CNC equipment

Not to be used for wet painting

If you are an expanding manufacturer or new business,we can provide the necessary assistance in planning your process.

More information,please feel free to contact us by the way as follow: