- Home

- About us

- Products

- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

- Faqs

- News

- Certificate

- Contact us

mini spray booth

- group name

- Powder Coating Gun

- Min Order

- 1 piece

- brand name

- COLO powder coating equipment

- model

- COLO-S-03

- Nearest port for product export

- SHANGHAI, NINGBO, QINGDAO, GUANGZHOU

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union

- Export mode

- Have the independent export and import right

- update time

- Fri, 30 Jan 2026 07:55:41 GMT

Paramtents

Condition New

Type Powder Coating Booth, Portable Powder Coating Gun

Substrate Aluminum

Coating Powder Coating

Voltage 380V

Power(W) 3.6KW

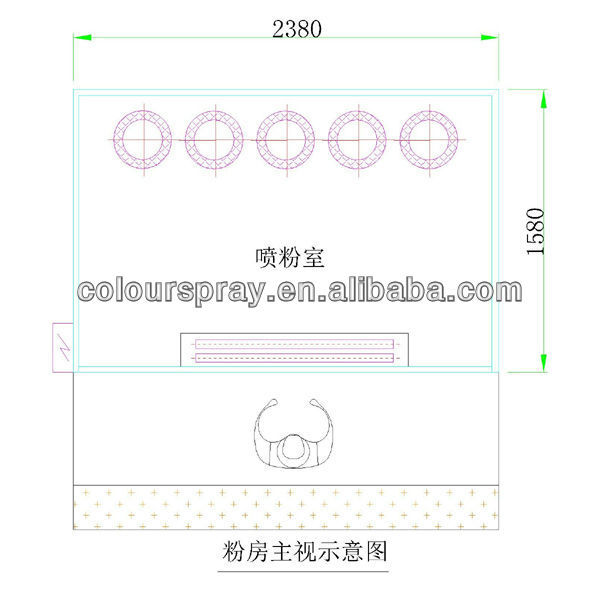

Dimension(L*W*H) W2280mm D1580mm H3000mm

Weight 400KGS

Certification CE

Warranty 1 YEAR

After-sales Service Provided Engineers available to service machinery overseas

kit powder coating

powder hopper 4L(2.5kg)

advantage change powder color quickly

Packging & Delivery

-

Min Order1 piece

Briefing

2,Production capacity and operational efficiency

3,Easy for change color

4,longer last

5,CE

Detailed

Electrostatic powder coating booth,

mini spray booth

The powder booth fans draw air through filters and releases it through the top of the booth. It keeps your shop nice and clean,minimizing powder dust.

Benefits of our powder booth

- Operator Safety

- Environmental compliance

- Production capacity and operational efficiency

- Easy for change color

- longer lasting, more durable, quieter

include fans, motors, nut and bolt fasteners, filters, detailed drawings and instructions, all included in one single shipment.

Data:

One door

Size: W2280mm D1580mm H3000mm / W2380mm D1580mm H3000mm

Body material: δ=1.5mm galvanized plate

Pulse valves and solenoids

Air velocity 0.6m/s

Recycling fan1/set 4-72-3.6A 3.6 KW

Fliter number 5pcs/set Flither

sizeφ325×900 fast-loading

light: 220v 36w 2 pcs

Voltage is 380V /50HZ (could make as you want)

During operation overspray powder accumulates on the cartridge filters. As the cartridge filters load, airflow decreases and the negative pressure rises within the air handler. A timer activates a system of air purging valves that clear the cartridge filters of the accumulated powder to ensure maximum flitter life.

COLO are specialized in complete electrostatic powder coating line, paint coating plants ,curing and drying ovens, cartridge type and cyclone recovery systems, spray booth, conveyor systems, Also we are supplier of powder coating, powder filters, powder coating machine,powder coating equipment,powder coatting gun,,Reciprocator, painting guns, pumps and their equipments.