- Home

- About us

- Products

- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

- Faqs

- News

- Certificate

- Contact us

Powder coating machine System electric curing Oven

- group name

- Powder Coating Oven

- Min Order

- 1 piece

- brand name

- COLO powder coating equipment

- model

- COLO-1864

- Nearest port for product export

- SHANGHAI, NINGBO, QINGDAO, GUANGZHOU

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union

- Export mode

- Have the independent export and import right

- update time

- Sun, 01 Feb 2026 18:00:58 GMT

Paramtents

Condition New

Type Coating Production Line

Substrate Iron

Coating Powder Coating

Voltage 380V/220V

Power(W) 1200W

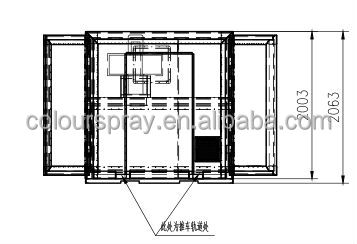

Dimension(L*W*H) 1900 width x 2200 height x 1700 depth

Warranty 1 Year

After-sales Service Provided Overseas service center available

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Electrostatic powder coating oven

1,Full automatic control 2,Small area occupation 3,Low energy consumption 4,size is customize

5, the heating by gas or electric or fuel ect ,pls choose 6,max temperature degree ? mostly are 160-200 degree and some user for specially ,powders need about 400 degree

7,Burner is RIELLO

8,Electrostatic powder coating oven, machine to make powder coating 9,used for curing the workpiece which has been spraying during the powder coating.

Model | Colo-1864 |

Worksize dimensions | 1600width x 1800 height x 1400 depth |

Overall dimensions | 1900 width x 2200 height x 1700 depth |

Power supply | Electric/ 12kw |

Voltage/Frequency | 380V/220v(50-60hz) |

Warm-up time | 15-30 min. (180° C) |

Temperature stability | < ± 3-5°C |

Temperature max. | 250° C |

Ventilation performance | 805-1677m3/h |

Motor power | 0.75kw |

Circulation/ Air flow | Vertical ,Variable through holes on the walls |

Transportation | Trolley |

Warranty | 12 months |

Small powder coating Oven

When a thermoset powder is exposed to elevated temperature, it begins to melt, flows out, and then chemically reacts to form a higher molecular weight polymer in a network-like structure.

- Structure:consist of Body,insulation, cover, heater. use gas to create the energy ,through thecirculating fan ,make the temperature in the oven to rise uniformly. Then make the temperature of workpiece to rise.

built-in track to roll your powder coating racks into the ovens could be ordered together as you required.

Powder coating spray Booth

This powder coating machine spray booth is popular size for small shops measures 1700mm in height by 2400mm in width by1 500mm in depth . Our Powder Booths make efficient use of shop space and are designed for manual “batch” or automated/process powder coating with or without overspray reclamation. Shop air is drawn into the powder coating spray booth, and then passes through the powder booth’s workspace into a filtered plenum integrated into the wall(s). The air is filtered in multiple stages and then discharged to the outside atmosphere or routed back into the room. Disposable filters are easy to inspect and replace.

COLO are specialized in complete electrostatic powder coating line, paint coating plants ,curing and drying ovens, cartridge type and cyclone recovery systems, spray booth, conveyor systems, Also we are supplier of powder coating, powder filters, powder coating machine,powder coating equipment,powder coatting gun,,Reciprocator, painting guns, pumps and their equipments.

Electrostatic powder coating manufacture in China,Electrostatic Powder Coating Machine,Powder spraying gun, powder spray gun, metallic powder coating system, electrostatic powder spraying unit, electrostatic powder spraying.electrostatic spray application system,Surface Finishing Equipment.